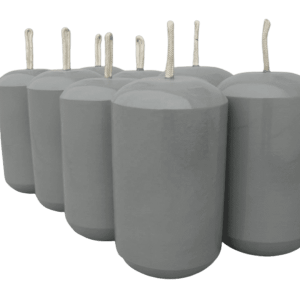

Boat Side Foam Fender

EVA Foam Fender is made from a core of closed-cell EVA (Ethylene Vinyl Acetate) which is covered with a Tough Abrasive Resistant Flexible Polyurea Elastomer Skin. Foam Fender is more and more used on boat side, tow and hull.

Additional information

| Size Customized | Yes |

|---|---|

| Color | Red, Yellow, Orange, Blue……Or Others Customized |

| Layers | No |

| Material | EVA Foam, Polyurea |

| Protection | SPUA |

Product Details:

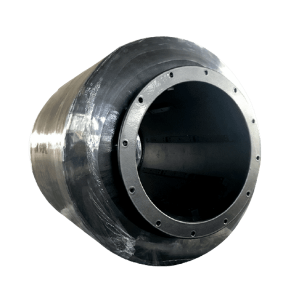

EVA Foam Boat Side Fender is made from a core of closed-cell EVA (Ethylene Vinyl Acetate) which is covered with a Tough Abrasive Resistant Flexible Polyurea Elastomer Skin. Foam Fender is more and more used on boat side, tow and hull.

Advantages of EVA Foam Boat Side Fenders

- Light Weight: Foam and Polyurea are light materials. Foam fenders can reduce the weight of the boat and increase the loading capacity.

- Durability: The life of foam fenders can be 10-15 years.

- Customization: Foam fenders can be manufactured in different shapes, sizes, and lengths according to the boats’ shape and installation.

- Versatility: Foam fenders can be used for kinds of boats.

- EVA cell closed Foam advantages: good buffering, earthquake resistance, heat insulation, moisture resistance, chemical corrosion resistance, non-toxic, non-water absorption, strong and durable, low maintenance cost.

- Spray Polyurea Elastic(SPUA) surface advantages: prevent ultraviolet light, waterproof and anticorrosive, wear resistance to thorns, and resist parasitic Marine organisms. Color can be customized according to the Pantone color card.

Applications of Boat Foam Fenders

- Boat side/hull foam fenders are mostly used for yachts, business boats, working boats, assault boats, tug boats, navigation boats, etc.

Please do not hesitate to drop us a message if you have any questions or demands.

Get Quick Quote Within 24 Hours

Why Choose Wingo Marine Products

Have passed ISO9001, ISO14001, OHSAS18001 certification; Weapon equipment quality management system GJB90001B-2009 certification; The drafter of Chinese standard HG/T5327-2018 for “Floating Rubber Fenders”.

Manufacturer

More than 30 years manufacturing experience, 6 endineers, 70 skilled workers, 36000 square meters workshop.

Lab Support

Technology research and innovation of rubber & SPUA (Spray Polyurea Elastic) are from the key universities and national labs.

Project Design

Experienced engineers checked your requirements with salesa manager together. The professional design can be provided when you needed.

Quality Raw Material

High-quality rubber and high-quality HDG accessories are used. Make sure the fenders have a longer service life.

One Stop Service

Help purchase other marine products and ship them together. Free storage until shipment.

Quick Shipping

40 KMS away from the wharf, no need to lease a warehouse in advance. Many cooperative forwarders, choose the best shipping plan for you. Save your time and money.

Fast Certificate

Get the following third-party certificates quickly. CCS、DNV、GL、LR、ABS、BV、NK、KR, RS, etc. Many of them have offices in our city.

After Sales

Tools and instructions for routine repair are provided with the goods. Under warranty the damages caused by quality problems will be free replaced instead of maintenance.

FAQ

What Are Your Warranty Terms?

Warranty is 12 months. Design life is 6-12 years. In case of quality issues during warranty, the supplier is responsible to repair or exchange. After-sales service will be executed in time.

How Do You Make The Appearance Inspection?

Smooth and streamlined body, no cracks or bubbles or impurities or obvious dirt or other defects.

What Type Of Payment Do You Support?

Usually we support T/T payment. If there are special needs, L/C can also be supported. Other payment methods need further communication.

Can You Help Us Purchase Other Products?

Of course. We often help our clients to purchase other items. Sometimes there is sapce in the container. It can save freight for you.

How long is the delivery time?

Depends on the type and quantity of fenders. Our factory has been little affected by COVID-19. Most orders can be finished in one month.

Do You Have Agents Abroad?

We have a branch in Hong Kong. They are also a great team. You can get same good service from them.

What Kinds Of Accessories Can You Supply?

Inflation tools and repair kits are supplied with pneumatic fenders. If there is no high pressure air system, air compressor will be supplied.

Are The Chains & Flanges Made Of Stainless Stell?

No. All metal parts contacting with sea water such as flanges, bolts, pins etc adopt HDG steel. Zinc coating has good corrosion resistance and is cheaper.

What Certifications Can Be Supplied?

Mill Inspection certification and Certification of Conformity will be provided at the delivery of the fenders. Third party’ certification such as CCS, BV, ABS are available at buyer’s request and cost.

What Is The Main Material Requirement?

(1) Pneumatic rubber fender adopts mixed natural rubber, with 60-64% rubber. (2) All metal parts contacting with sea water such as flanges, bolts, pins etc adopt HDG steel. (3) Inner layers is special air sealing layers. The outer rubber layer is UV-proof and anti-abrasion. Between them are rubber layers reinforced with cord net. The vulcanization time is 5 to 7 hours.

Can You Quote With CIF Price?

Yes, we can. We have long-term cooperation with the freight forwarder, can get a good freight quotation. Which can help top save your cost.